THE CHALLENGE

Hypocalcemia, colloquially known as Milk Fever, is a common metabolic disorder caused by severe calcium deficiency most prevalent in dairy cows. This disorder has clinical and subclinical levels of severity, the latter often going undetected due to lack of symptoms. Without treatment, up to 60-80% of cases result in death. Further, milk fever significantly reduces milk yield and productivity. However, hypocalcemia is difficult to detect until symptoms are present, at which point the cow has reached an advanced disease state.

OUR SOLUTION

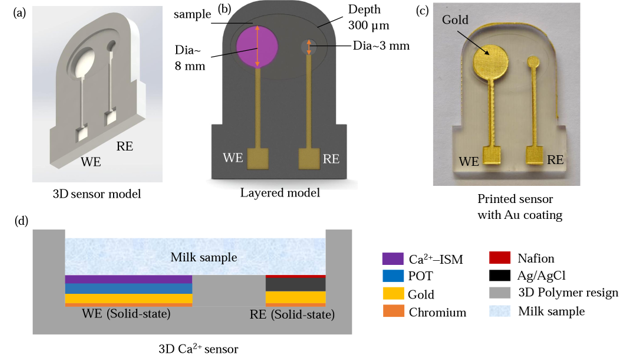

The Ali lab has developed a low-cost, portable, 3D printed solid-state sensor for the detection of calcium levels in cow’s milk. Advances in the electrode design enable highly sensitive detection down to attomolar concentrations. Further, the sensor can also detect phosphate ions and thus, the sensor can detect the ratio of calcium to phosphate concentration in milk samples. Milk analysis could be an ideal approach to knowing the hypocalcemia status in dairy cows instead of analyzing blood samples. This sensor platform can be easily adapted to other ions by switching out the ion-selective membrane.

Figure: Cross Section and overview of the invention

Advantages:

- Ease of manufacturing: This sensor can be quickly and cheaply manufactured using 3D printing, giving farmers a low-cost solution to detect the prevalence of hypocalcemia in dairy cows.

- Facile use: The small portable nature of this sensor allows point-of-care use, allowing farmers to monitor the calcium levels of their herd without costly and time-consuming laboratory testing.

- High-resolution detection: The sensor can detect the calcium levels at attomole concentration within a minute. Furthermore, sensors can be integrated with milkers for continuous monitoring.